Specification

-

Smart Filter is the top level of Hydraulic Automatic Filtre technology that ACRV reached

-

Compared to other produced filters for same aim in sector

-

SMART filter design which is high engineering product, has superior features

-

This model can be used alone in open channels as the filtering area is wider

-

Due to the excess of permeability, it becomes contaminated later than the eco model

Explanation

- Self-cleaning ACRV Filter systems;It can be used in agricultural irrigation systems,industrial facilities alone or in tandem as well as in combination with additional equipment such as hydrocyclone, gravel – moss filtration, pomp suction filter.

- Control systems with pressure regulator can be adjusted with the pressure difference.

- In electronically controlled systems, it can be adjusted both with the pressure difference and at desired periodic times.

- Selection is optional.

- Automatic filtration systems made from rustproof materials are manufactured to operate at a maximum of 10 bar input and a minimum of 1.5 bar output pressure.

Superior Features

- Through improved regulator control system adjustable cleaning time.

- Can operate efficiently even under reduced pressure.(1,5bar).

- Can complete self-cleaning by drain more less dirty water.

- Can clean it’s self in short time

- Low maintenance costs and simple control.

- High power vacuuming of cleaning nozzles.

- Can observation some of reactions during cleaning.(Opservation Tube is Optional).

- High torque of rotor.

- Can clean sieves by nozlle as well as brush.

- Real suppor of coarse sieve to thin sieve. (1500 Micron).

- Can display coarse sieve pressure, thin sieve pressure and clean water pressure. (3 unit manometer).

- Ergonomik

- Higher performance in hard conditions (very intensive pollution).

- Can protect control system from air pressure may occur in filter.

- Ergonomic structure

Advantages

- Automatic filtering systems are designed from carbon steel and stainless steel.

- Selection is optional.

- Provide filterin between 50 and 200 micron.

- Starts self cleaning when pressure difference reached the specified value.

- Self cleans in short time without interrupting water flow and water flow continues in system.

- Thanks to the modular and simple structure provides solution for different capacities (16m3 and 320m3) .

- Products can mount on the trailer or over the floor linearly to corners.

- Products are made cleaning with chemical metal after testing in 10 bar pressure.

- Later paints with zinc-based primer and topcoat electrostatic paint in oven

Working Systems

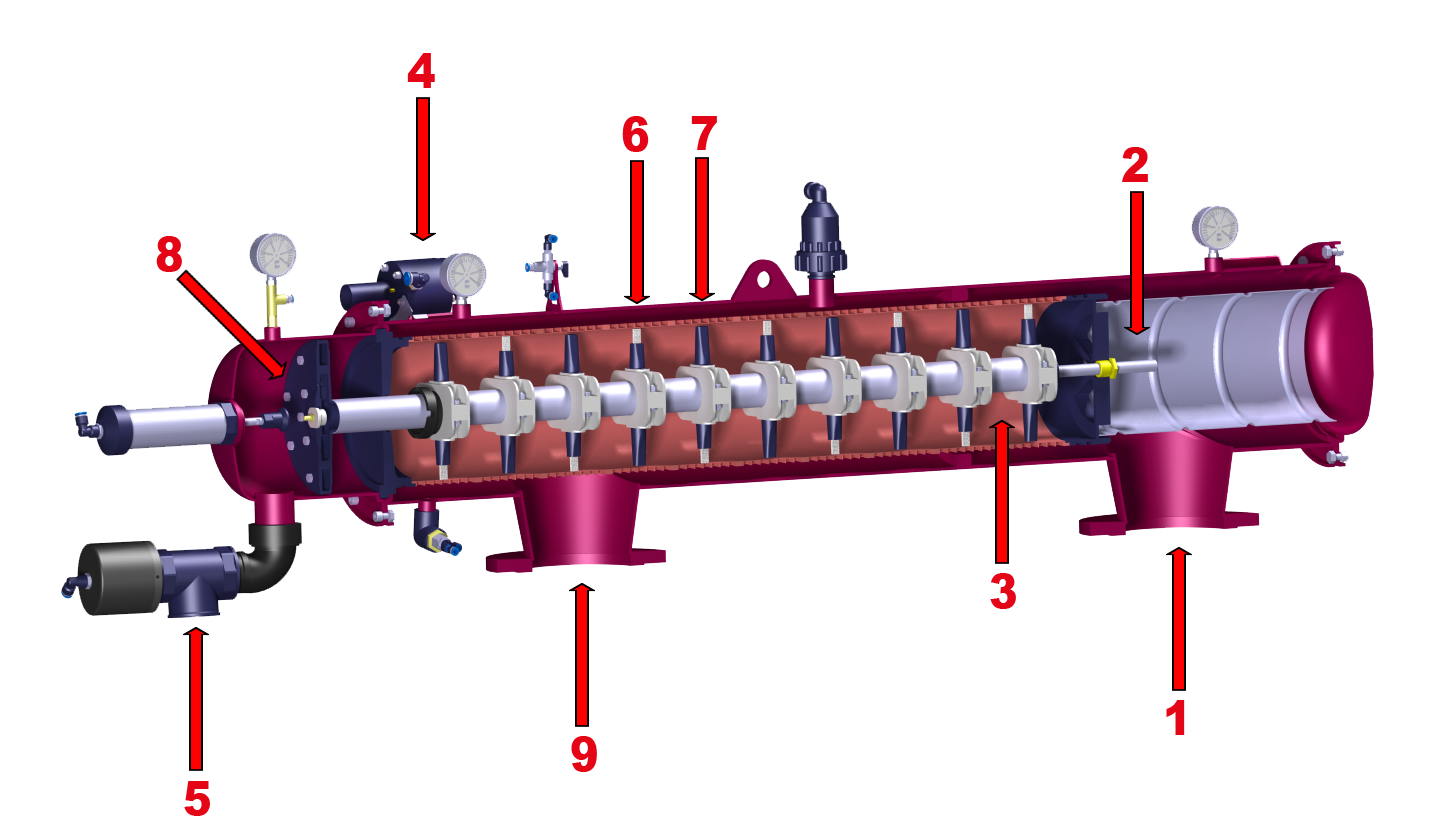

- (1) Waterentering to system in maximum of 10 bar inlet pressure,

- (2) Filtration process is starts while polluted water moving coarse sieve. In this section, large particulers are seperated from water to prevent harm of the inner part of the filter components and helps become more efficient implementation of the filtering process. Free of large particles in still polluted water passes through the fine sieve have smaller pores inner

- (3) and filtering process is completed. During the process of filtering particles are deposited on the fine sieve will cause clogged pores and differential pressure. Pressure regulator or the electronic controller opens drainage part

- (4) and water begins to drain

- (5) when pressure difference, on the emergence of a set level. Vacuum force occur during drain provides for the absorption of dirts by aids of brushs

- (6) – (7) During drainage of dirty water, provides rotation of the turbine

- (8) and gives nozzles and brushes axial and linear movement, so cleans sieves completely. Filtere water given the system from clean water outlet

- (9) System continues to operate without interruption during filtration.

Specification